Manufacturing On Demand

The 3D Printers can improve the efficiency of your production runs and accelerate your product development cycle by manufacturing on demand.

With 3D printing, you can quickly and easily create custom parts and prototypes, reducing the lead times and costs associated with traditional manufacturing processes.

It is a sustainable manufacturing process that reduces waste and material costs. 3D printing uses only the exact amount of material needed for each part, leading to less material waste and a more environmentally friendly production process.

Coupled with the fact we produce all our items in the UK, manufacturing with The 3D Printers reduces your carbon footprint as well as your lead times.

“We found The 3D Printers on an internet search and chose them as they were local to the FC we work in. We need mass-produced parts and they delivered. Fantastic people to work with. Warm and friendly with excellent communication. The work produced is of the highest quality. Would not hesitate to recommend.”

Paul R London

Our Manufacturing Services

We work with a range of clients from distribution and fulfilment centres for major retailers requiring a streamlined consultancy, design and production solution to individual designers and engineers needing prototypes and testing.

Depending on your need, we can offer a full problem-solving production service from design to manufacturing, or advise or any individual element of the process.

- Product design tailored to your specific requirements – our engineers take time to fully understand your requirements, the purpose of the item, the environment and your budget, ensuring we are able to give you the perfect solution from every angle.

- Pre-production samples – these can be supplied within 48 hours of design sign off, allowing you to rapidly test your products before committing to large orders.

- Express Service – depending on the size of the items and quantity required, and where a completed STL file is available, we are able to create small production runs the same day. Please call us in advance to request this service, as every project is individual. (NB the Express Service carries an additional charge to our standard 3D printing services.)

- Production runs – on a daily basis we produce production runs of between five and 1000 parts. We offer engineering-grade materials and cater to a wide range of industries as well as individuals.

At the 3D Printers, we’ve seen demand growing for low volume production (also known as low volume manufacturing). We work with many manufacturing clients on product design and low-batch production, assisting with the product or part design, producing prototypes and then producing the finished product.

3D printing for low volume manufacturing

The flexibility of 3D printing means it is ideal for short-run manufacturing, and for producing solutions for warehouse settings. On small manufacturing runs we can produce anything from one to several thousand parts, each one of a consistently high quality, and with rapid turnaround and delivery times.

Our bespoke manufacturing service offers far more than simple 3D printing. Our custom manufacturing service means we are able to help our clients turn a simple sketch of an idea into a final product. Through a highly personalised process of consultation, engineering, design, prototype and manufacture we can often go from idea to a product in your hand in a matter of hours.

3D printing for bulk manufacturing

Advances in 3D printing have even made it possible to bulk manufacture large numbers of parts in a single production run. By optimising the build area to minimise unused space, we can produce large quantities of parts on demand, eliminating the need for you to hold large quantities of stock, freeing up costly storage space and reducing your inventory costs.

Read more: https://the3dprinters.co.uk/manufacturing-in-bulk-using-3d-printing/

3D printed parts for warehousing solutions

3D printing allows you to produce custom parts quickly and affordably. This is especially useful in warehouse settings, where there is a high demand for unique, bespoke parts. By using 3D printing, warehouse managers can create parts tailored to specific requirements, rather than relying on off-the-shelf solutions that may not be suitable or cost-effective. From widgets to bespoke brackets and equipment mounts for specific locations, 3D printing provides maximum flexibility.

Read more https://the3dprinters.co.uk/revolutionizing-warehouse-operations-with-bespoke-3d-printed-parts/

3D printing offers –

- increased flexibility when creating custom or low-volume parts

- faster production times for small to medium-sized batches

- reduced waste of materials

- the ability to create complex shapes and internal structures

- easy customisation for specific applications

Our team of 3D printing specialists has extensive experience in designing and producing custom parts that meet specific requirements. We work closely with you to understand your needs and create parts that are tailored to your operations.

Our state-of-the-art 3D printers can produce parts quickly and affordably, ensuring that you get the parts you need, when you need them.

Whether it’s a bespoke bracket, holder, widget, or any other 3D printed part, we have the expertise and technology to deliver high-quality solutions.

We offer a full problem-solving consultancy and design service, with rapid response and fast turnaround.

Project examples

Warehousing solutions

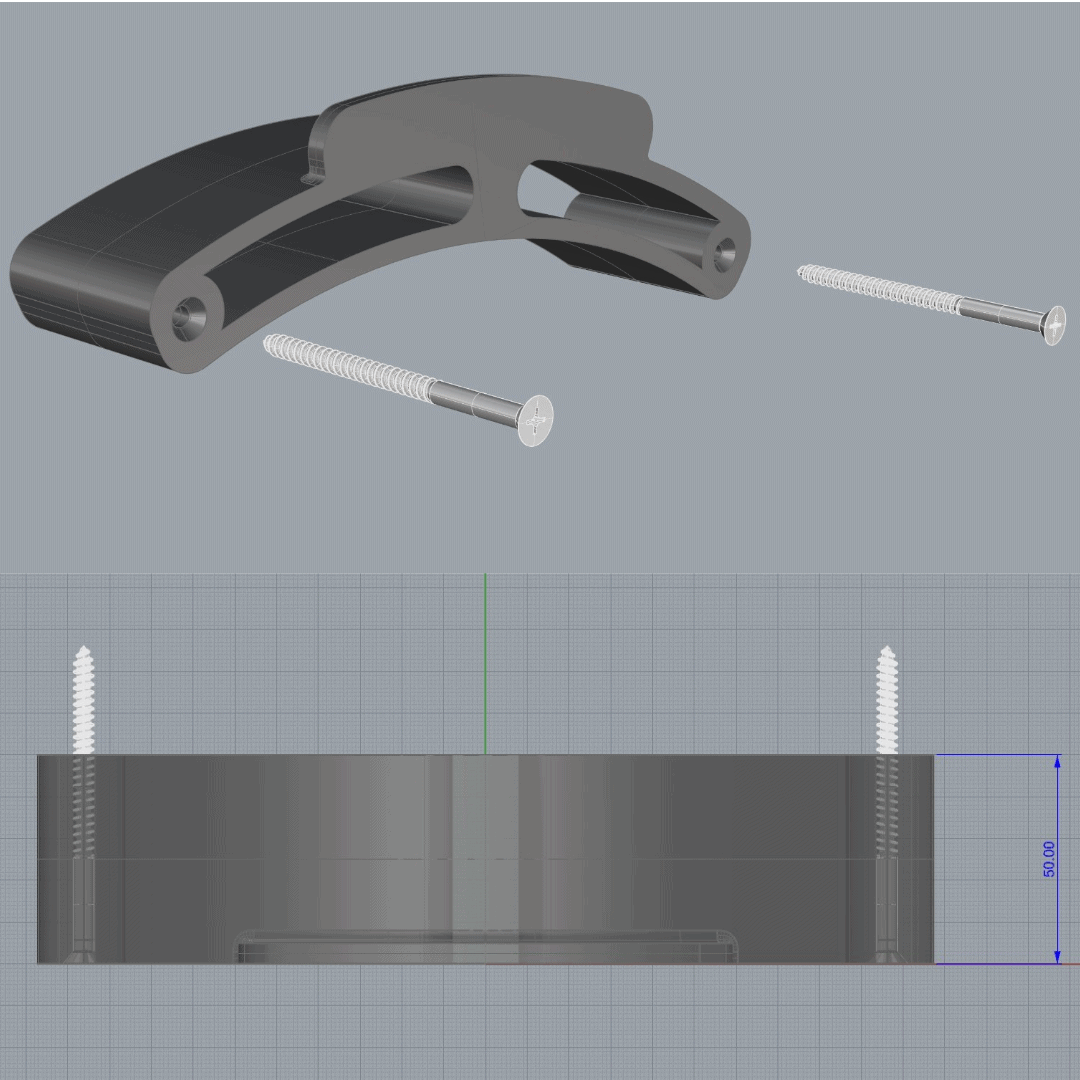

Fulfilment centres and factories across the UK and Europe rely on us to design and manufacture clips, brackets and widgets.

We work closely with them to create the perfect design, reducing their costs on machinery downtime and engineer repair time.

We then manufacture the products and parts, fulfilling orders varying in number from 100’s to 1000’s of parts. The process of consultation, prototyping and production sets us apart in our field.

Rapid-response solution – Unistrut sensor brackets

The client needed a solution to attach sensors to their Unistrut system. Our engineer discussed the required outcome with them, and designed and digitally created the perfect, completely bespoke solution. We created a product sample within three hours of the initial request – delivered the next morning. The client was amazed by how perfect it was and ordered 15 more sets for delivery the following day.

Large manufacturing run

Our client sent us a file, and we sent a sample. The result wasn’t what they had hoped for, as the part broke too easily for the heavy-duty job it did. We took the client’s design and improved it for strength and flexibility, sent a sample and it was perfect. They then ordered 1800 more with complete confidence that this was the perfect part for them. These parts have now gone on to become best practice within their organisation.

Highly detailed art sculpture

The client needed a delicate approach for his latest digital sculpture, which demanded a smooth but highly detailed result. We advised on processes, materials and finishes to create the perfect result.

Film props

For the film ‘Gravity’ we spent many weeks creating the detailed parts you see in the Shenzou capsule.

GET IN TOUCH to discuss your needs now.

BRINGING YOUR IMAGINATION TO LIFE

Bespoke 3D printing services for every client

Drop us a message with your details and attach any .stl files you have. We'll be intouch ASAP.

For all press enquires please contact Jane Baerselman at jane.baerselman@tealcommunications.co.uk

![Invicta Chamber Logo gotham [Converted] kent Invicta Chamber Logo](https://the3dprinters.co.uk/wp-content/uploads/2022/04/Chamber-Member-Logo.jpg)