The 3D Printers – 3D Printing service, serving London & the whole of the UK

Our 3D printing service is used to fabricate high quality prototypes, props and products. We are able to produce products in a variety of materials to create strong, durable and even flexible items.

Whatever your requirements, we are sure to find a solution for you. Our 3D print farm consists of many different machines to create beautifully crafted 3D prints. We offer a fast turnaround and an exceptional eye for detail.

To Discuss a 3D print service project: Call 01233 556 055

Our 3D printing Processes

At The 3D Printers, we offer a number of different printing technologies, depending on the individual needs of your project, and what you want to achieve from it.

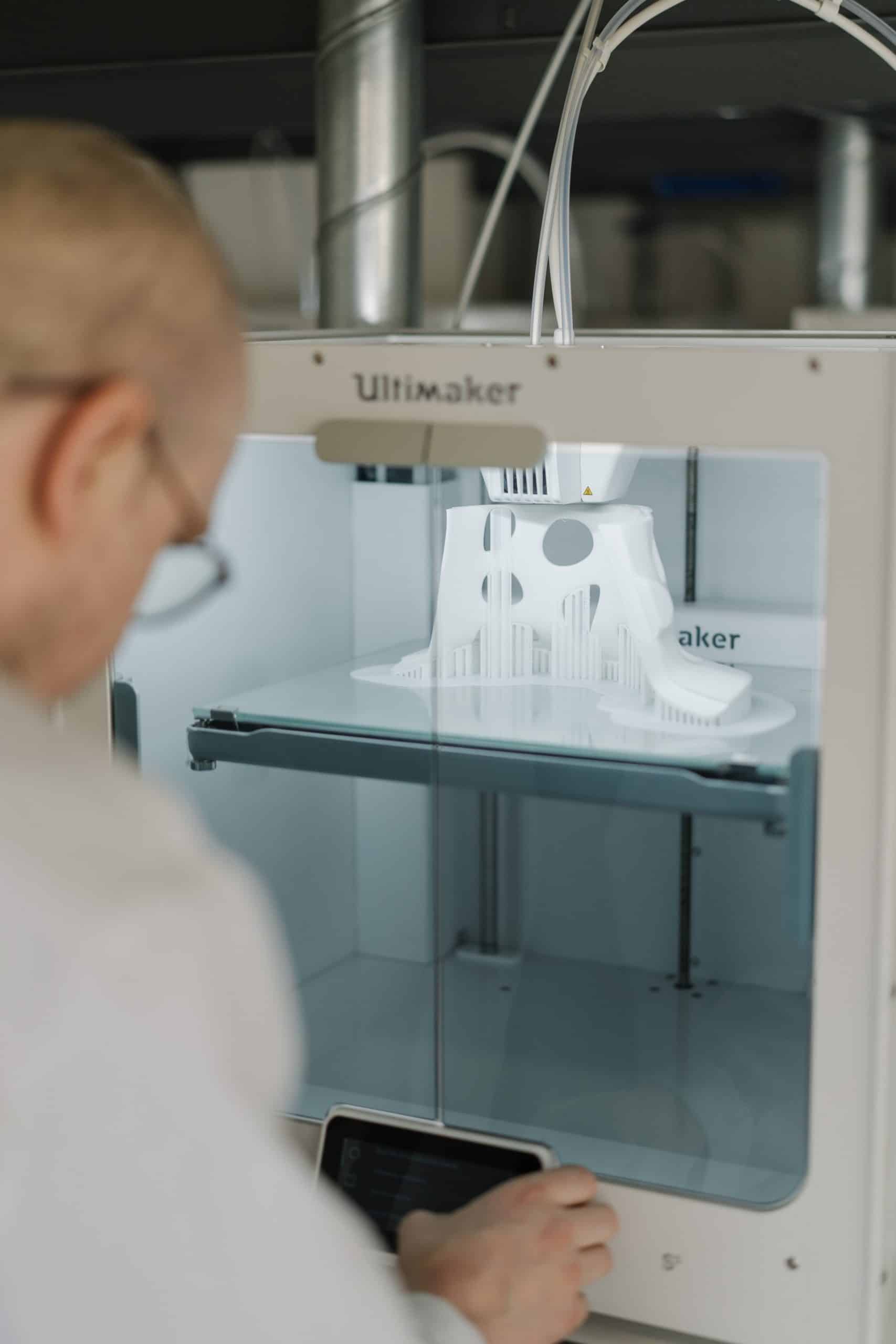

FDM Printing

Fused Deposition Modelling, or FDM, is a widely available 3D Printing technology.

It works by selectively depositing liquid plastic to build a part in layers, defined by the modelling software, which creates slices from the CAD drawing to build the path the extrusion nozzle will follow. It’s a heat-based technology, where a thermoplastic filament is heated until it becomes semi-liquid.

Once the 3D print is made, any additional supports required during the process can simply be broken or washed off.

FDM printing can make use of a wide range of materials, including (but not limited to) PLA, ABS, PETG, nylon, and TPU. This makes it possible to print anything from small, intricate designs to large functional parts, and with specific properties such as flexibility, strength, and temperature resistance.

FDM printing inherently produces less material waste than other 3D printing technologies, making it a more environmentally friendly option.

At the 3D Printers our state-of-the-art machinery and full consultancy service will ensure that you achieve the best strength and tolerance possible, as we will work out the best way to print your design for optimum results.

FDM 3D printing is ideal for:

- Shapes with complex geometries and cavities – the layer-by-layer printing method allows for the creation of highly intricate and detailed objects. FDM printing also allows for support structures, which can be used to create overhangs and other complex features without compromising the structural integrity of the final product.

- Products with tight tolerances – FDM printers offer high precision and accuracy, which is essential for products with tight tolerances. The printers can produce layers with high resolution resulting in highly precise and accurate products.

- Speed – one of the primary advantages of FDM printing for prototyping is its speed. FDM printers can produce models in a matter of hours, allowing designers to quickly identify potential issues, iterate and modify their designs.

- Environmental Challenges – Prototypes that need to withstand temperature changes, mechanical stress or chemical corrosion can be catered for using a wide range of materials.

- Testing and verifying CAD design models for strength and durability – producing prototypes quickly and at a low cost allows designers to test and verify their CAD design models before investing in expensive tooling and equipment.

- Production runs – FDM printing is a fast and efficient process that can produce production runs quickly, eliminating the need for expensive tooling and equipment and reducing the overall cost of production compared with traditional manufacturing methods.

SLA Printing

Stereolithography, known as SLA, is the most widely used resin 3D printing technology.

It’s an industrial 3D printing process ideal for prototypes and parts, including gears, cogs and any other interactive pieces, as it provides the greatest level of accuracy and surface finish of any of the 3D printing processes.

SLA printing gives a smooth, almost porcelain-like finish, also making it ideal for 3D printed jewellery or other items with fine detail.

It works by using a computer-controlled UV laser beam or DLP (Digital Light Processing) technology, turning photo-sensitive resin into a solid, and building up layers of cured resin to create a completed version of your CAD model.

Once complete, any additional resins and support structures are removed using solvents before a final UV curing process fully solidifies the part.

It’s also fast, and, once cured, can be enhanced with a range of finishing and painting services.

SLA is ideal for:

- Low-volume manufacturing – including moving parts such as cogs and gears where accurate, fine detail is vital.

- Artists and sculptors – creating highly detailed and intricate sculptures and art pieces.

- Jewellery and products with extra-fine details – the ability to produce intricate and complex designs with fine details makes it ideal for the jewellery industry.

- Dental models and surgical guides – when using specialist resin SLA is used in dentistry to create dental models, surgical guides, and other dental appliances. The precision and accuracy of SLA make it ideal for creating dental devices that fit perfectly in a patient’s mouth.

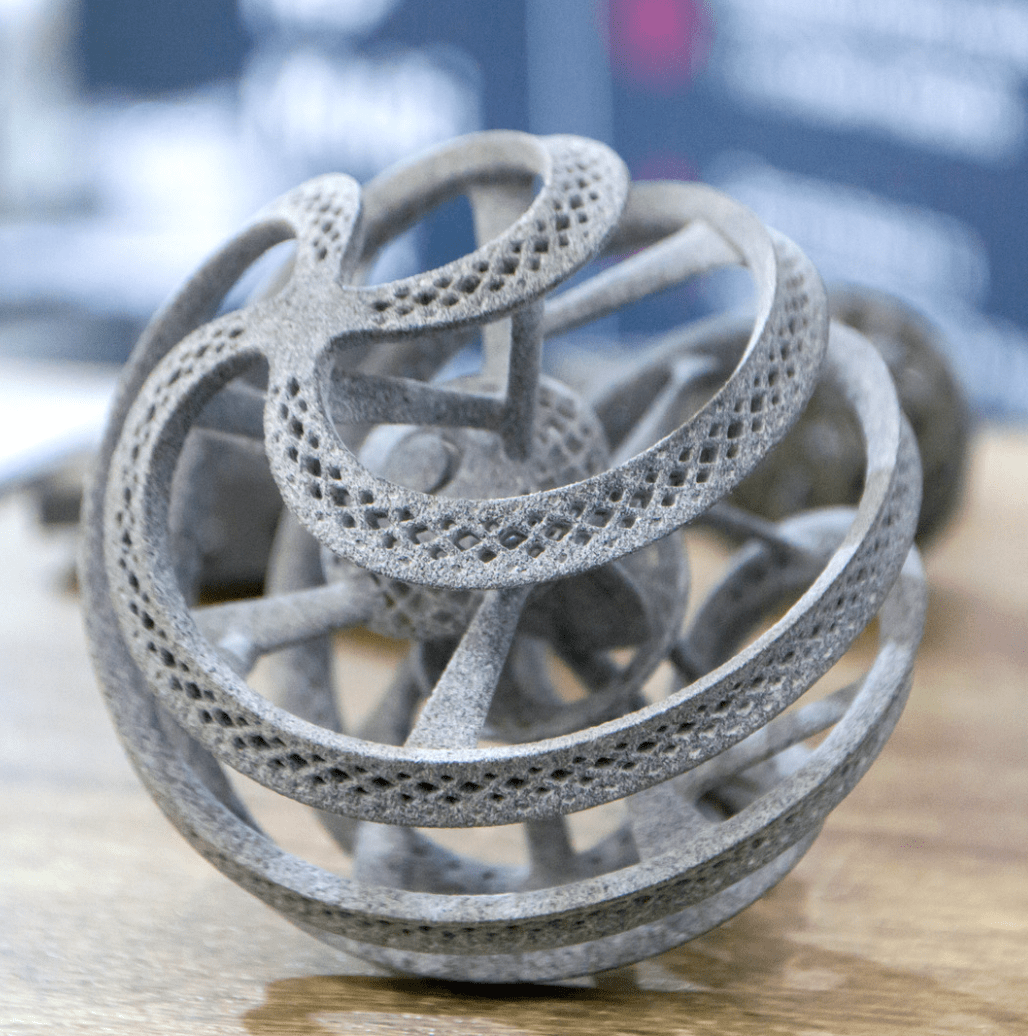

SLS Printing

Selective Laser Sintering (SLS) is an additive manufacturing process. In SLS 3D printing, a laser selectively sinters the particles of a polymer powder, fusing them together and building a part or model, layer by layer.

SLS uses thermoplastic polymers that come in a granular form, which are heated to a temperature just below melting point, causing them to fuse together and form a solid part. The material can be coloured to create a more durable coloured finish than is possible with painting.

SLS is a versatile solution, and provides a cost-effective alternative to injection moulding for low-volume manufacturing runs (fewer than 1,000 units), either as a final product, or to test your product or part before committing to the cost of making injection moulds for larger runs.

SLS has a wide range of applications in multiple industries, including automotive, aerospace, medical, and consumer goods. It is particularly useful for creating small, complex parts and prototypes, as well as for low-volume production runs.

SLS is ideal for:

- Low-volume manufacturing runs or test runs – especially for parts or products which incorporate complex geometries or internal structures that are difficult or even impossible to create using traditional manufacturing methods.

- Fast and accurate prototyping of new designs – allowing for rapid iteration and optimisation of product designs.

- Producing parts with consistent mechanical properties – the laser scanning process allows for precise control over the heat distribution, resulting in parts with a uniform microstructure and mechanical properties.

We have built a reputation for Excellent customer sevice, bespoke design, high speed manufacturing and high quality products.

Why Choose The 3D Printers - Your Ashford 3D printing service

Experienced Designers

We have been producing exceptional 3D designs and prints for over 15 years.

Professional & Friendly Staff

As a family run business we take huge pride in our services. From the first interaction to the final product.

On Call 24/7

We are available around the clock for all your 3D printing needs.

Express Turnaround

We offer an express turnaround to ensure we get your print to you as fast as we possibly can.

Personal Service

We are extremely passionate about our customer service. From the moment you contact us you will be looked after!

Extensive 3D print service experience

We've been designing and creating for over 15 years. Originally specialising in Movie props, creating high quality items is in our DNA.

BRINGING YOUR IMAGINATION TO LIFE

Bespoke 3D printing services for every client

Drop us a message with your details and attach any .stl files you have. We'll be intouch ASAP.